EXPERT PLANT RECOVERY SAVES $6.5 MILLION FOR ASSET OWNER

SITUATION

SITUATION

Whipping winds, torrential downpours, power outages, and floods — hurricane season is hard to miss. And with 2020’s Atlantic hurricane season ranking as the most active on record, owners of utility solar plants are bracing themselves for costly damages in the future.

When two hurricanes swept through the Southeast in 2018, one asset owner faced torrential rainfall and massive flooding at its 92-MW PV plant. The damage was severe: Ten of 40 power conversion stations were inundated with 12 to 18 inches of water and remained flooded for several days.

The operator took all of the plant’s inverters offline before the hurricanes roared through, generating condensation inside all of them. Consequently, when the inverter manufacturer inspected for damage at the plant, it voided the warranty on all 40 inverters — instead of the 10 flooded units — abruptly denying responsibility for any of them.

SOLUTION

DEPCOM Power’s restoration teams looked at all aspects of the project to keep costs and revenue loss to a minimum. From damage assessment and salvage planning to rapid restoration, they quickly assessed the situation: Condensation in the inverters was the long-term result of poor design and not negligent maintenance, as the OEM reported.

DEPCOM Power equipment specialists determined that the doors on the damaged units were not sealed properly, allowing humid outside air to seep in, resulting in condensation.

With this expert documentation in hand, DEPCOM Power provided the critical proof that the units had pre-existing design issues, compelling the OEM to restore the warranty on the 30 inverters that had not flooded. Insurance covered the ten flooded inverters.

RESULTS

Facing significant production losses already, the plant owner and its insurance partner were on track to replace the flooded inverters. But DEPCOM Power’s specialists offered a different solution: Salvage and refurbish the units and save a whopping $4 million in equipment replacement costs. The insurer approved the plan but wanted to be sure the inverters were flood-proof. The most cost-effective solution? Elevate the concrete pads supporting the units by three feet for a fraction of the replacement cost.

One of DEPCOM Power’s unique strengths is prioritizing workflow to minimize revenue loss. In this case, it applied a strategic approach to move the restoration worksite to an area that would not hamper power production in other sections of the site.

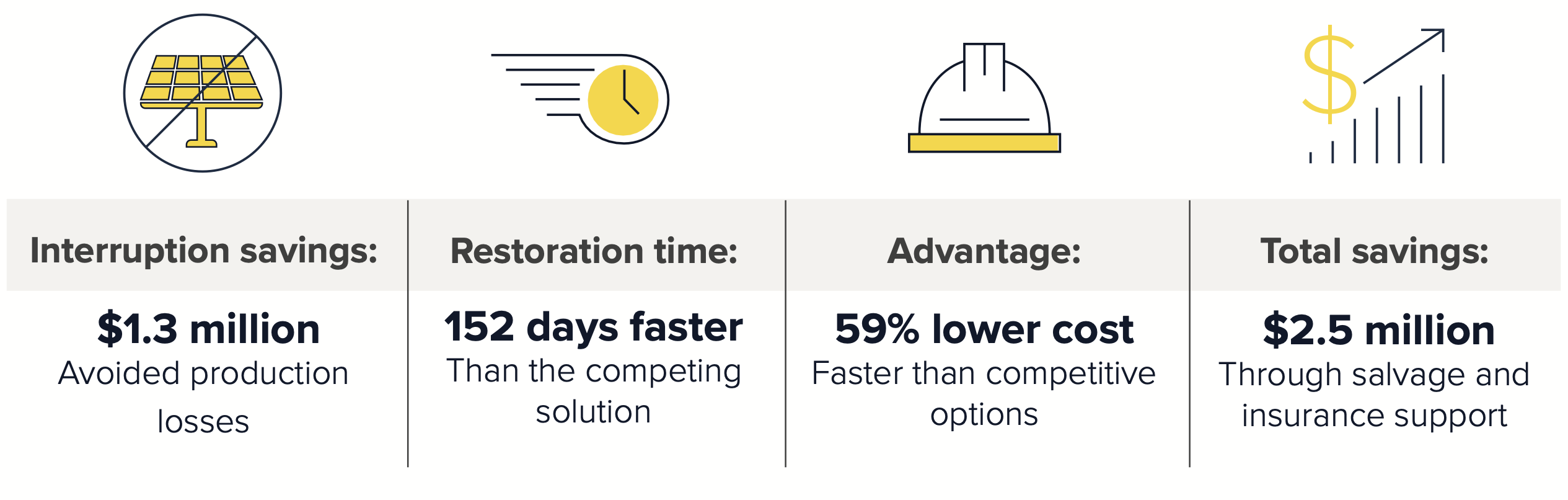

As one of the country’s leading EPCs with more than 1.5 GWs of operational solar projects, DEPCOM Power can mobilize quickly. It deployed its 24/7 operational crews to the site to lift the pads in just six weeks, far faster than the 22-week lead time required to install new inverters. This efficient solution minimized business interruption and got the flooded portion of the plant back online.

As one of the country’s leading EPCs with more than 1.5 GWs of operational solar projects, DEPCOM Power can mobilize quickly. It deployed its 24/7 operational crews to the site to lift the pads in just six weeks, far faster than the 22-week lead time required to install new inverters. This efficient solution minimized business interruption and got the flooded portion of the plant back online.

DEPCOM Power’s ability to rapidly return the plant to production resulted in $400,000 to $700,000 more revenue than waiting for the delivery of new inverters. Combined with the $1.8 million savings from salvaging the flooded units, DEPCOM Power’s fast restoration plan resulted in total savings of more than $2.5 million for the asset owner.

Keeping everyone on the same page was critical. DEPCOM Power’s proactive communication between the owner, the insurance providers, and the partners wove the team together for an efficient collaboration.